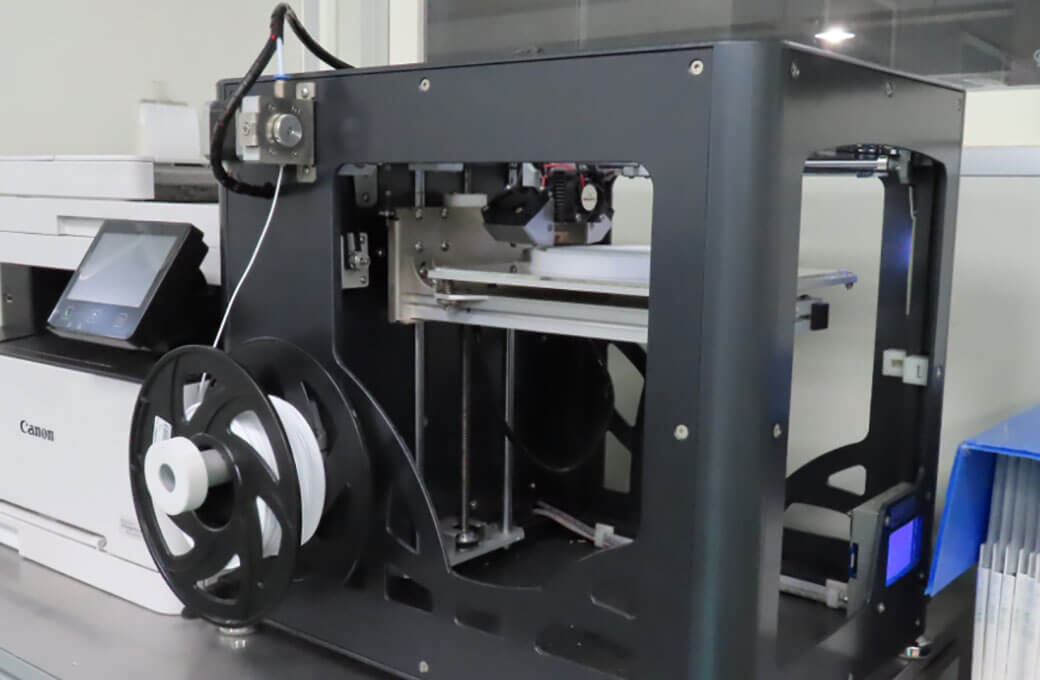

3D printing, also known as three-dimensional printing, additive manufacturing or layer-by-layer manufacturing. It is a technology that builds objects by layer-by-layer printing using adhesive materials based on digital design model.

3D printers is a type of industrial robots. The most prominent advantage is that digital models could be designed directly from the computer without machining or any molds. It help manufacture large and small parts required by the industry, which is faster and more accurate than traditional parts. Thus, greatly shortening the product development cycle.

Living Fountain takes advanced 3D printing technology. After the final confirmation of the 3D design draft with the customer. We would use 3D printing to produce the printing sample for customers to confirm. And the confirmed sample would be so as to assist in the actual size of the product, packaging, labels, gift boxes, etc. for the final confirmation. It would also help to improve R&D production efficiency.

Adhering to environmentally friendly principles, Living Fountain utilizes 3D printing with PLA (Polylactic Acid) extracted from corn starch. The material is eco-friendly, with high stability in output. It provides easy support removal, contributing to more efficient processing.